The rise of e-commerce companies has lead to a boom for terminal distribution centers. A significant part of the manpower and overall operation of distribution centers involves picking orders, packaging, and shipping orders. Equipment like the battery-powered terminal tractors from DJ Products can help maximize manpower, reduce injuries, and save money.

The following are a few more tips that can help improve the efficiency of your terminal distribution center:

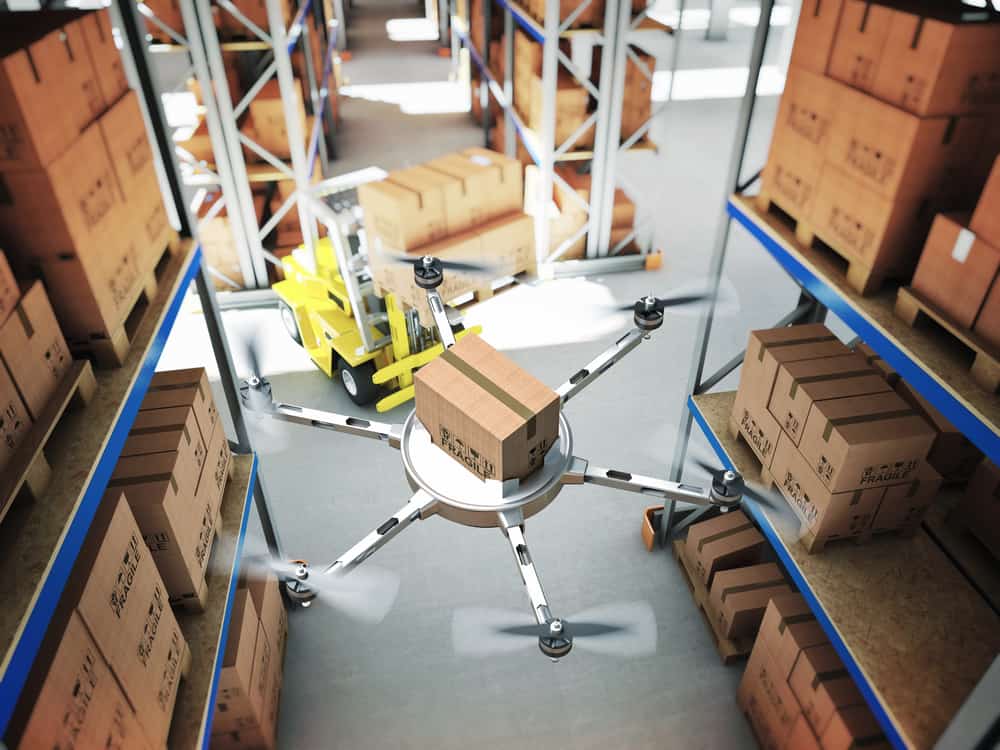

Utilize available technology

There have been some extraordinary advancements made in the area of industrial robots in recent years. Along with robots, there are now smart conveyor systems, and warehouse management systems (WMS) that not only keep things running smoothly but also make tracking incoming shipments and monitoring inventory easier than ever before.

Innovations like the TrailerCaddy Terminal Tractors from DJ Products reduce injuries to employees and damage to trailers and buildings.

Improve inventory management

By keeping inventory low you spend less effort managing products that are sitting on the shelf. There are WMS solutions to help monitor inventory in real time and lower costs due to damaged products.

Frequently evaluate your processes

People working on the floor are the first to notice problems and can identify areas that are not flowing as efficiently as possible. Be sure your warehouse personnel know their input is heard and appreciated. People work more efficiently when they are not fatigued or overexerting themselves. Incorporate equipment that allows one person to do the work of several both easier and safer.

Consult with experts

If you’re looking for ways to reduce workers comp claims, lower operational costs, and increase productivity, contact one of the knowledgeable and courteous sales engineers at DJ Products for a consultation about your businesses and which products are best for your needs.