Shipping companies are expected to form alliances in order to provide high-quality services to their customers in 2019. In addition to these alliances, investing in terminal tractors and other products can help these companies improve productivity and raise morale among their employees. Taking these steps can guarantee being able to provide superior service.

Logistics and Shipping Changes

Logistics companies and shipping consolidation have led to fewer carrier options for shipping companies. This drop in available carriers can make it difficult for shipping companies to ensure that they are able to keep products moving on schedule and get the quality they are looking for. This is especially true for independent shipping companies compared to much larger ones.

Some shipping companies have decided to form alliances, so they can do business with carriers that they can depend on. Making this move will help these companies protect their business.

Pros and Cons of Consolidation

Is consolidation a positive or negative change for shipping companies in general?

Consolidating has pros and cons that shipping companies should take into consideration. These alliances allow shipping companies to thrive and stay on schedule overall. However, shipping companies might find that rates end up increasing due to a lower amount of competition in the market. These rate increases could have a negative impact on shipping companies.

With alliance formations expected to continue this year, it’s important for independent shipping companies to weigh the advantages and disadvantages of consolidating before making any decisions on whether or not to go through with it.

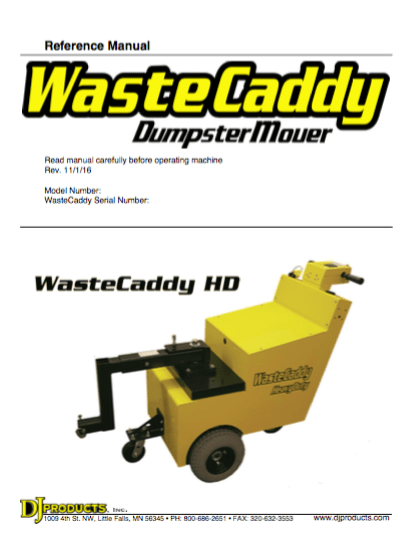

If you need more information on terminal tractors for your warehouse, contact DJ Products. These products can help improve working conditions for your employees, which boosts productivity and saves on time.