Industrial ergonomics plays an important role in protecting workers from injuries. The use of ergonomics in warehouses and similar workplaces where manual labor is done helps ensure a safer environment. This type of design reduces injuries workers can get from doing repetitive tasks or pushing or lifting heavy loads. A simple change, such as using a motorized trailer dolly, can help support ergonomic design in these settings. Learn more about the kinds of benefits industrial ergonomics provides.

Increased Productivity

Workplace injuries, such as muscle strains, can make it difficult for workers to be productive. A loss of productivity can have a negative impact on your business. Ergonomic equipment makes it easier and more comfortable for workers to handle everyday tasks, resulting in increased productivity.

Better Workplace Safety

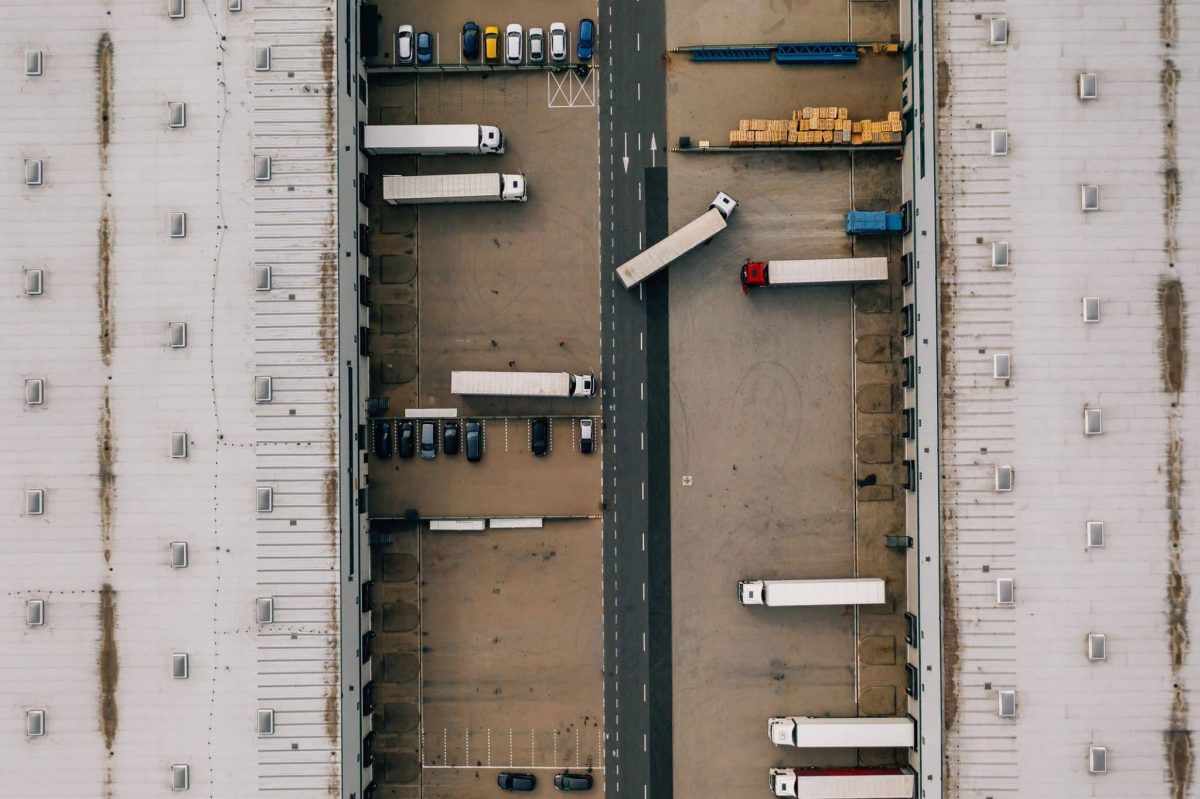

Operating forklifts, manually pushing heavy loads, and doing other tasks in industrial settings comes with a wide range of risks and safety hazards. Using ergonomic design and equipment, such as motorized trailer dollies, helps boost safety in the workplace and reduces the risk of injuries.

Reduced Costs

Workplace injuries and accidents can lead to high costs for companies in terms of workers’ compensation, healthcare costs, and staff turnover, and decreased productivity. Ergonomics helps keep these costs low through higher productivity, improved safety, and stronger employee morale.

More Employee Engagement

Providing a safe and comfortable workplace environment for workers helps reduce the risk of having them leave. This helps keep employee turnover lower, so companies don’t have to spend significant time and money finding and training new staff. Having happier employees thanks to industrial ergonomic design also helps increase productivity.

Improved Service or Product Quality

When workers have injuries or fatigue on the job, this can lower the quality of products or services they handle from day to day. Making changes in the workplace through ergonomic design and equipment can help improve product or service quality. This helps companies boost customer satisfaction.

If you’re looking for a motorized trailer dolly for your workplace, please contact DJ Products. Our team can assist you in finding one that fits your needs, so you can enjoy the benefits that ergonomic equipment provides.