In the world of heavy-duty trailer movement, efficiency and safety are paramount. Enter the TrailerCaddy, a game-changing solution designed to simplify the process of moving trailers, whether in a warehouse, manufacturing facility, or distribution center. This innovative motorized trailer dolly offers unparalleled power, versatility, and ease of use, making it an essential tool for businesses that handle heavy trailers regularly.

Unmatched Power and Performance

The TrailerCaddy is equipped with a robust motor that generates significant power, allowing it to move trailers weighing up to 50,000 lbs. This impressive capability is due to its heavy duty 36v motor and hydraulic actuator motorized lift kit, which can lift tongue weights from 6,000 to 15,000 lbs. Whether you’re dealing with RVs, horse trailers, toy haulers, or large boats, the TrailerCaddy handles them all with ease.

Versatility at Its Best

One of the standout features of the TrailerCaddy is its versatility. It comes with various attachment options, including ball hitch, kingpin, and pintle attachments. This flexibility ensures that the TrailerCaddy can be used with different types of trailers, making it a valuable multi-purpose unit. Additionally, its size and maneuverability make it an affordable alternative to traditional tractors or pickups.

Ideal for Indoor and Outdoor Use

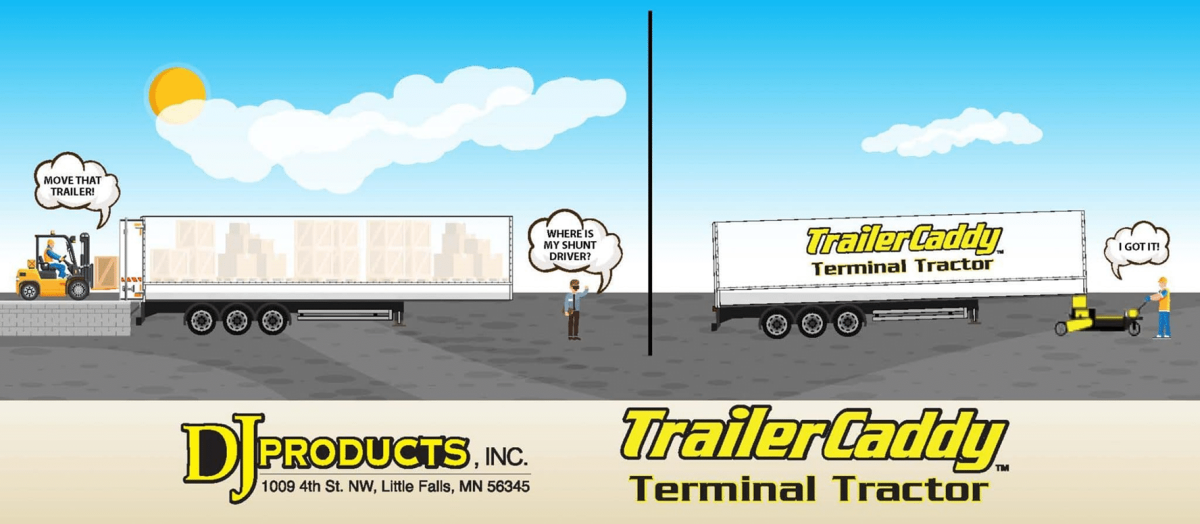

The TrailerCaddy is designed to perform exceptionally well both indoors and outdoors. Its variable speed control allows for precise maneuvering in tight spaces, while its durable construction ensures it can withstand the rigors of outdoor use. This makes it the perfect solution for manufacturers, warehouses, and distributors who need to move heavy trailers short distances efficiently.

Enhancing Safety and Efficiency

Safety is a critical concern when moving heavy trailers, and the TrailerCaddy addresses this with its optional powered brake release system. This feature enhances control and stability, reducing the risk of accidents during trailer movement. Moreover, the TrailerCaddy’s ease of operation means that employees can quickly learn to use it, improving overall efficiency and productivity.

Customer Testimonials

The TrailerCaddy has received glowing reviews from users who appreciate its performance and reliability. Customers have praised its ability to move heavy loads effortlessly and its user-friendly design. One satisfied user mentioned:

“The TrailerCaddy moves my 13,000 lb. trailer around like it is a little red wagon.”

Such testimonials highlight the TrailerCaddy’s effectiveness and the positive impact it has on daily operations.

Conclusion

The TrailerCaddy is a revolutionary tool that transforms the way heavy trailers are moved. Its powerful motor, versatile attachments, and user-friendly design make it an indispensable asset for any business that deals with heavy trailers. By enhancing safety and efficiency, the TrailerCaddy ensures that trailer movement is no longer a daunting task but a seamless and straightforward process.

Explore the TrailerCaddy and experience the future of trailer movement today!