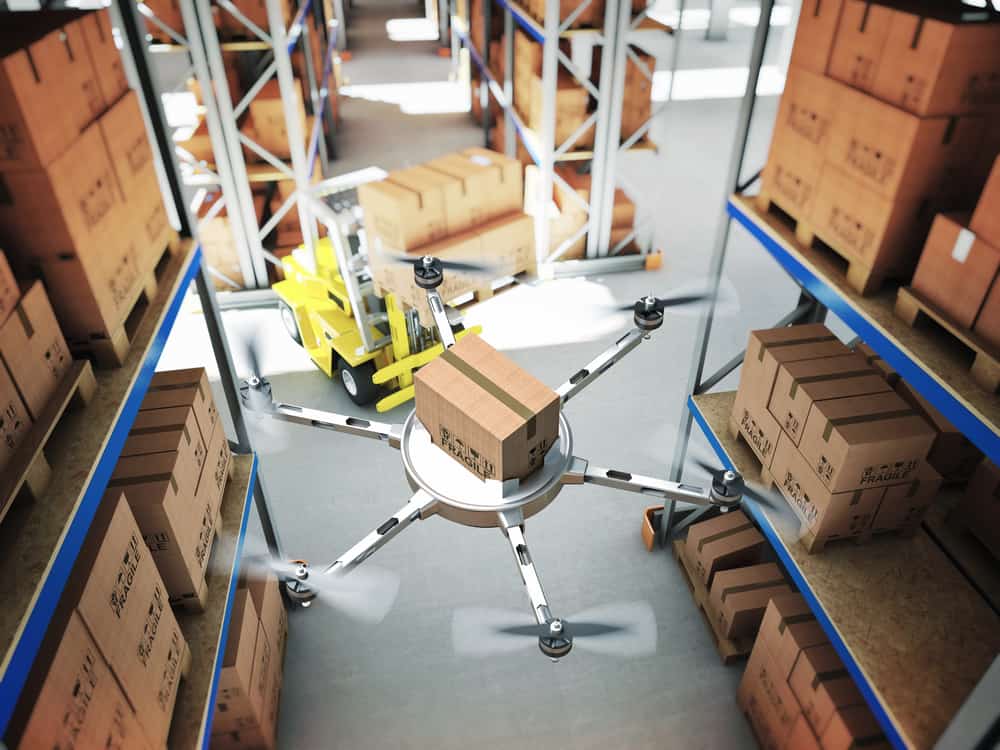

Warehouse management can often feel like a circus juggling act as you struggle to keep everything up in the air. Does your warehouse equipment help or hinder productivity in your warehouse? Here are four more tips to help you “keep your eye on the ball” and optimize warehouse efficiency.

Tips for Improving Warehouse Efficiency

1. Keep Aisles Clear of Obstructions

Leaving empty pallets or unshelved merchandise sitting in the aisles “just for a minute” can stretch into hours or even days, increasing the likelihood of accidents. Make sure employees are in the habit of keeping the aisles free of anything that doesn’t belong.

2. Optimize Warehouse Design to Meet Workflow Needs

Minimizing travel time is key to improving productivity. Design storage and layout of your warehouse to reduce the number of times a product has to be touched, eliminating need for time-wasters such as repalletizing or restacking.

3. Analyze Order Processing Cycle Time

Do you know how long it takes to process the average order in your warehouse? One distribution center was stunned to discover that less than 40 percent of their order processing cycle time was spent in actually working on the order. Analyze your current order processing steps and identify weak spots.

4. Establish a Culture of Safety

Workplace accidents have both short- and long-term effects on your overall productivity and the injured worker’s health. Enforce use of appropriate safety equipment, train employees in proper procedures and post safety tips and reminders in visible places.

DJ Products: Your #1 Choice for Safe and Efficient Warehouse Equipment

DJ Products offers a comprehensive line of battery-powered tugs, movers and pushers to accommodate the needs of any application. Visit our website and use the convenient online chat feature to learn more.