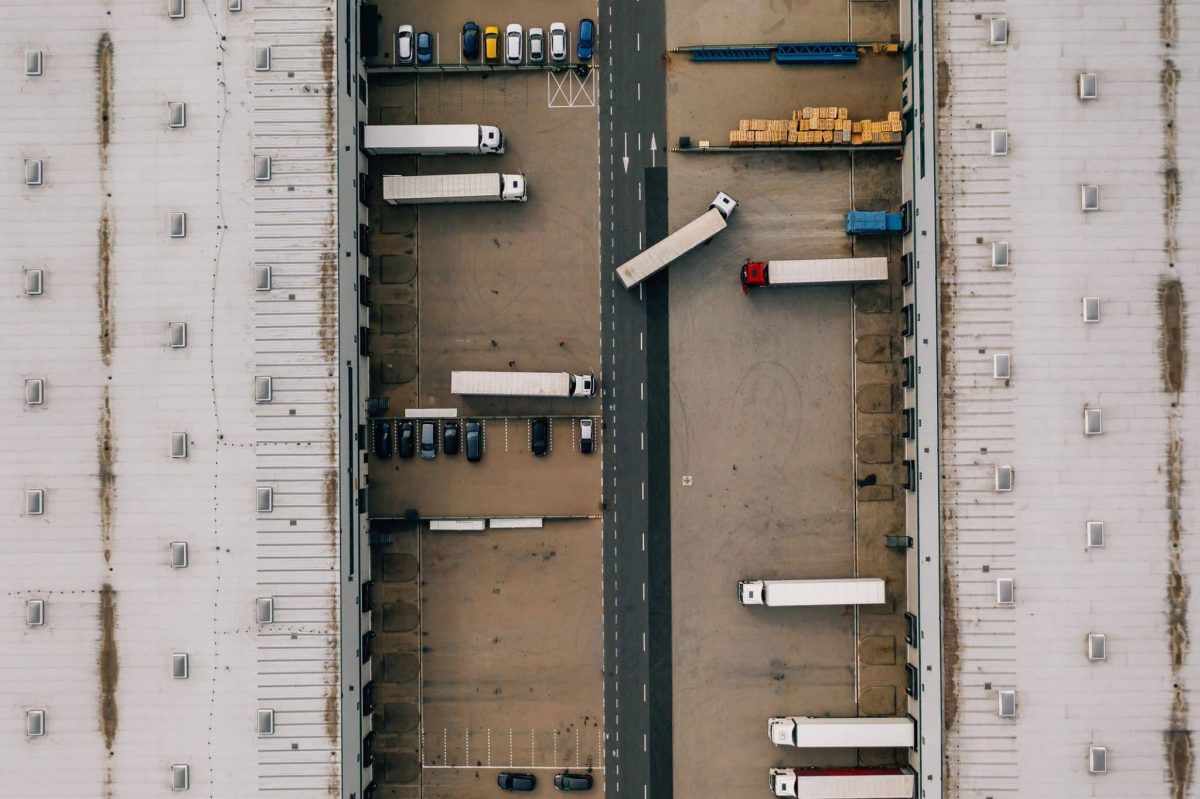

The mantra, “Work smarter, not harder,” certainly applies to warehouses and distribution centers. Excessive manual labor puts a serious strain, literally and figuratively, on your employees, here’s why you should consider replacing your manual material handling equipment with one of our battery-powered tugs, movers and pushers, such as the motorized trailer dolly.

The High Cost of Workplace Injuries

Musculoskeletal disorders, or MSDs, occur when the physical demands of a task go beyond the body’s capabilities. Injuries can arise from a single incident, or they may be the result of repetitive strain over time.

Each year, workers compensation claims due to MSDs total nearly $33 billion. Add in the indirect costs of reduced productivity, lost time and increased turnover, and it’s easy to see why employee safety should be a priority.

Types of Manual Material Handling Equipment

- Retrieval aids include basic transport equipment such as hand trucks and flat platform trolleys. While these devices are an improvement over carrying boxes and materials, they can be easy to overload and difficult to maneuver.

- Pallet jacks come in one-handed pull and two-handed push varieties. The former allows limited visibility, while the latter solves that problem but requires increased muscle activity to operate.

- Carts incorporate flat surfaces, bins and shelves on which materials are loaded. Height-adjustable carts that minimize the amount of lifting needed are generally preferable.

Benefits of Motorized Tugs for Material Handling

- Manual material handling equipment sometimes takes the efforts of two workers to operate efficiently. All of our motorized tugs can be used safely and effectively by a single employee, which particularly comes in handy with our motorized trailer dolly.

- All of our equipment is ergonomically designed to prevent chronic stress that can lead to repetitive motion injuries.

- Our movers are strong enough to handle tough jobs but compact for easy handling and maneuverability.

- Battery power eliminates noxious fumes and noise pollution.

Are You Ready for Our Motorized Trailer Dolly?

DJ Products has a full range of electric tugs, movers and pushers to accommodate any application. Contact us at 800.686.2651 and let our experienced Sales Engineers help you find the solution that’s right for your company.