Managing a warehouse is a constant juggling act as you work to control labor, inventory and freight. Tugger carts from DJ Products help employees be more productive. What other methods can you use to improve efficiency and reduce costs?

How to Reduce Costs and Improve Efficiency

Here are five top tips from experts to keep all three elements of your warehouse operations running at high levels.

1. Control Freight Charges

Freight charges can eat away at profits more quickly than any other factor. Skilled consultants can help you negotiate carrier agreements at lower rates without a corresponding decrease in service.

2. Develop Incentive Pay Programs

Incentive pay for performance is actually one of the more cost-effective methods to increase productivity. Review programs carefully to make sure they’re not redundant.

3. Simplify Workflow and Processes

Less really can be more. Take a look at the warehouse layout and work processes to see if you can identify any wasted space and motions.

4. Establish a Baseline and Benchmarks

If you don’t know where you started, how can you tell when you’ve reached the finish line? Determine the measurements you want to track and provide employees with regular feedback to get them engaged.

5. Invest in Manager Development

When managers are the weak leak, it impacts every area of your business. Make sure they have proper training and other tools they need to succeed.

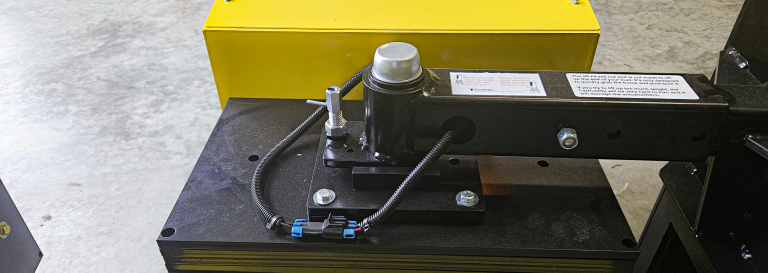

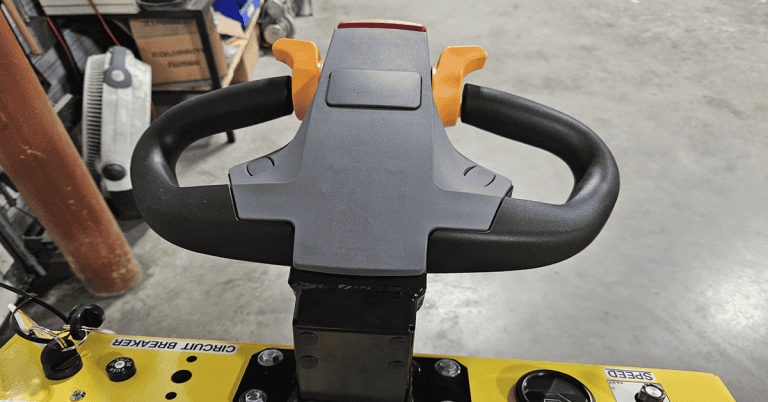

Streamline Warehouse Efficiency with Tugger Carts from DJ Products

Battery-powered tugger carts, such as our best-selling CartCaddyLite, promote higher levels of productivity and reduce costs through lower risk of workplace injuries.

Visit our website to learn more about our full line of material handling solutions. Use the convenient online chat feature to get real-time assistance from our sales engineers.