In our last post we talked about automation and how it is changing the face of the warehousing and distribution industries (see our Aug. 4 post). Automation allows businesses to handle greater volumes in shorter time periods. However, a major challenge in automating operations is the accommodation of unique customer requirements. Obtaining a customer’s business can depend upon your ability to meet their unique requirements. Doing so while maintaining a cost-effective operation can require both ingenuity and skillful management of material handling resources.

Tom Kozenski, VP of product strategy for optimization firm RedPrairie, suggested in a July 2008 Modern Materials Handling article that there are two ways to handle customer requirements: increase labor or engineer them into the normal workflow. “The first brings your operations to a grinding halt,” Kozenski said, citing the extreme cost. “The second allows you to differentiate your business from the competition.”

One way of engineering customer requirements into the workflow is to coordinate the delivery of components or raw materials to the production or assembly line with their use, Kozenski noted. Delivering materials to the assembly line in the same sequence that they will be used increases efficiency and production and, thereby, cost effectiveness. A combination of powered CartCaddies and pushers allows for maximum customization of this process.

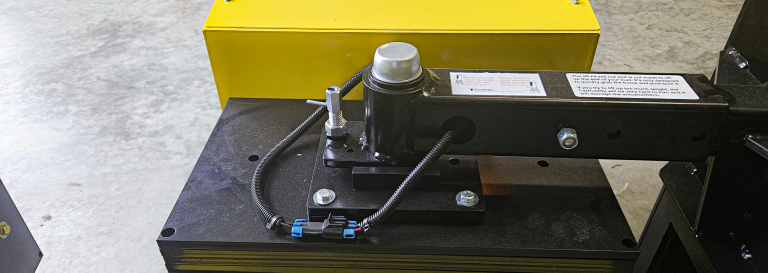

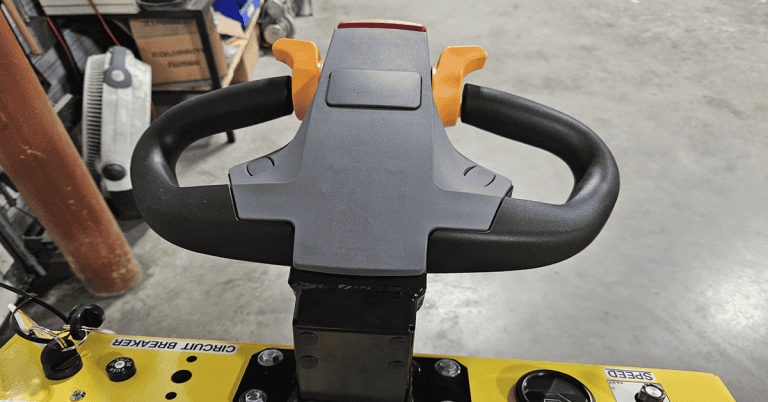

On an assembly or production line, electric CartCaddy power tugs can be used to push or pull carts loaded with customer’s specific components or raw materials. Carts can be preloaded and delivered to the line in sequence. In a vehicle assembly plant, for example, CartCaddy power tugs can be used to deliver windows, doors and other components to the appropriate point on the assembly line for sequenced installation. In a fulfillment operation, batched orders can be carted and delivered for sequenced processing. Highly maneuverable, ergonomically designed CartCaddy products maximize the load a worker can move safely, thereby limiting the number of workers involved in material delivery.

The CartCaddy electric tug or CarCaddy vehicle pusher can then move carts, equipment or vehicles from station to station down the line. CartCaddy products are available to move equipment across the floor on wheeled tugs or on a rail.