- Pushes Up To 20,000 lbs

- Pushes Paper Rolls and Wire Spools

- 36 volt 3 Battery System

- Adjustable and Custom Rollers

- 0-3 MPH Forward/Reverse

- Charger Works with 120/220 Hrz Outlets

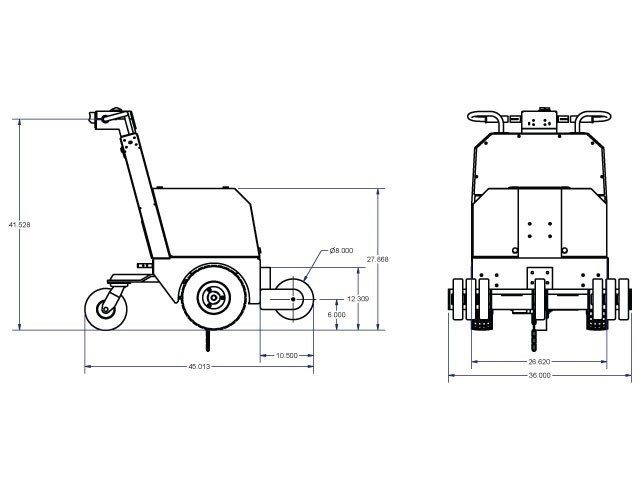

The CartCaddy powered paper roll and wire spool pusher eliminates the manual pushing and maneuvering of heavy, round products that turn/roll on their own axis. The custom, adjustable roller system mounted to the front of the CartCaddy pushes against the bottom of the round object, applying pressure to the CartCaddys drive tires for traction, while the rollers turn in the opposition direction rolling the reel forward. The operator uses the variable speed of the CartCaddys handlebars to slowly start the momentum of the rolling object forward without accelerating it too fast. As the operator slows the CartCaddy, the rolling object will also slow. The rollers extended outside the profile of the roll pusher help the unit pick apart rolls stationed next to one another.

The powered roll pusher provides directional force while the facility’s steering mechanism maintains the route of the cart. The CartCaddy roll pusher has been extremely successful in paper companies and for wire spool applications.

The CartCaddy battery powered roll pusher has been ergonomically created to prevent the strains and pains that are normally associated with manually pushing and pulling heavy carts and equipment. The use of the roll mover minimizes the risk of injury, which consequently reduces the number of workers’ compensation and insurance claims.

Fork trucks, walkies, and riding tugs are used often to maneuver carts and equipment short distances, but these solutions require considerably more storage space and are significantly more costly than the CartCaddy powered roll pusher.

Custom Powder Systems

Dew Engineering

McWane Ductile

Commercial Forged Products

Syracuse Housing Authority

Imperial Marble

Interstate U Stor

Commercial Forged Products

McWane Ductile

Commercial Forged Products

Stoody Co.

Cargill

Dew Engineering

Before you purchase, our sales and engineering teams work to make sure you get the right solution to fit all of your needs. During the sales and production process, our team will update you throughout, as well as sending pictures of your unit(s) and emailing shipping notifications with carrier and tracking information. After you purchase your unit, our sales team will follow up with you to make sure the equipment is working properly and fitting your needs. Our in-house tech support team is available to help you troubleshoot and diagnose issues via phone or email.

The CartCaddyLite electric cart puller can help avoid back strain for many people in the healthcare industry. Doctors, nurses, technicians, maintenance workers, and more can benefit from using this piece of equipment to efficiently complete some of their day-to-day tasks, all while avoiding unnecessary workplace injuries.

Linen carts used to transport linens to and from patient rooms are often very large and difficult to move through the constricted hallways of a nursing home, clinic, or hospital. Pushing carts repeatedly throughout the day can cause chronic neck and back strain and pain for workers. The CartCaddyLite is a perfect solution: it reduces stress and cuts down the risk of workplace injuries.