CartCaddy WagonWheel – Tugger

- Pulls carts up to 15,000 lbs.

- Works great on carts with tongues

- Attaches using ball, pintle, or pin hitch

- Stacked weight plates over transaxle for traction

- 36v – 3 Battery system

- Travels 0-3 mph

- Charger works with 120VAC-1Ph outlet

- Applications

- Video

- Features and Specifications

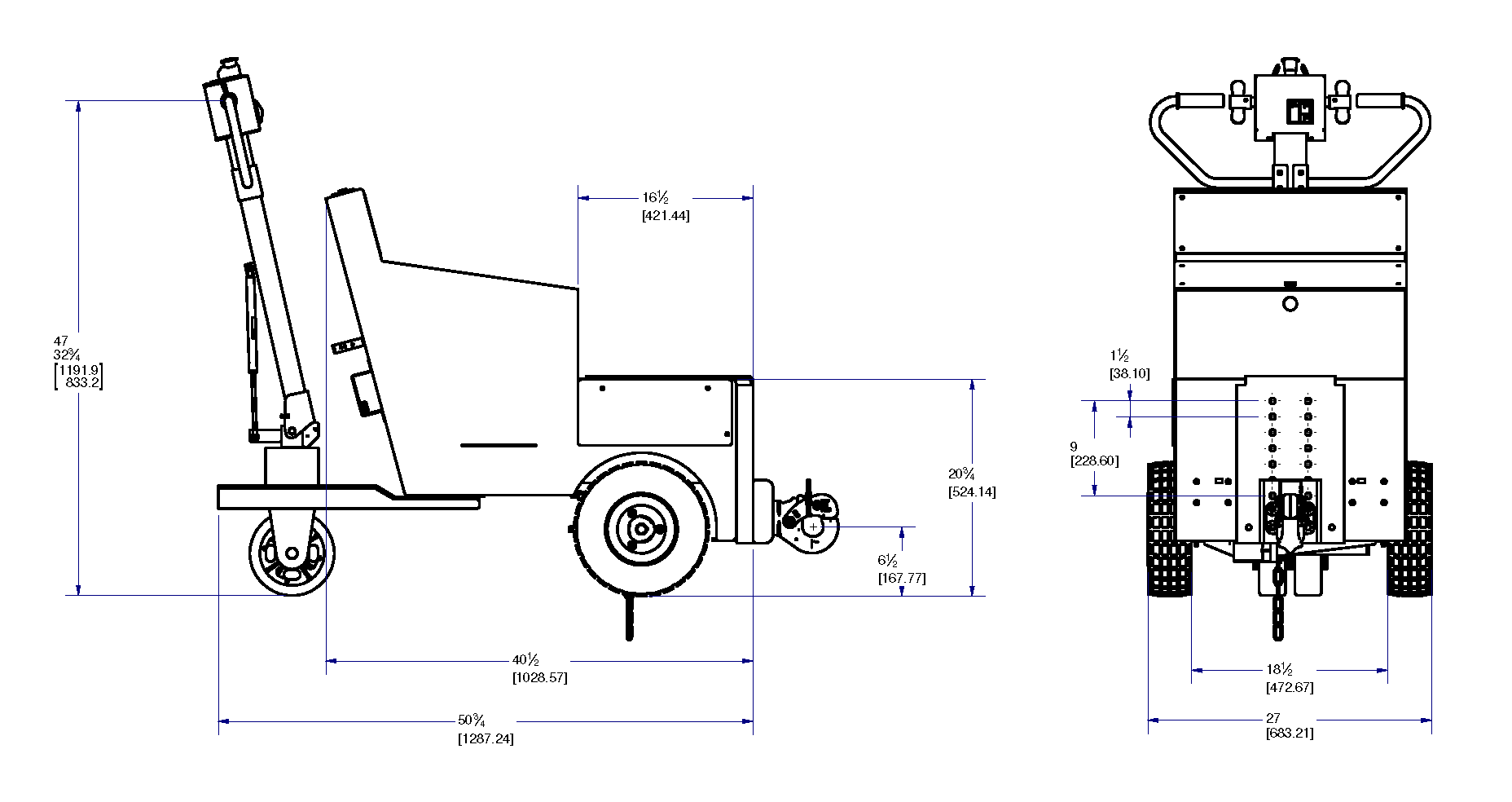

- Dimensions

The CartCaddy WagonWheel is manufactured to maneuver and pull trailers or carts with tongues that hinge up and down and can move an axle on the bottom of the cart. There’s usually a ring at the end of the tongues, which it can attach with a pintle or pin hitch. The CartCaddy WagonWheel gains its traction through the additional steel weight that has been installed on the top of the drive tires. This power tugger has a wagon wheel steering system, which allows for easier turning and movement. This works on carts and trailers that can weigh upwards of 10,000 lbs.

A common application is a trailer with quad steering wheels. This electric tugger can attach to the ring of the tow arm with either a pintle or pin, and it uses the power to pull self-tracking carts or a train while an operator turns the steering arm. This allows for intricate maneuvering. It can pull many items, from airport luggage, automobile parts in an assembly line, or heavy concrete slabs and forms across parking lots. As long as the heavy cart contains a swivel arm, the CartCaddy WagonWheel will almost always be capable of pulling it.

The CartCaddy WagonWheel comes with a standard 36v battery system (3 – 12v batteries) with 6-8 hours of continuous use in ideal conditions.

This unit has variable speed twist grip for forward/backward movements from 0 to 3 mph. The ergonomically designed variable speed feature prevents hand injuries and allows the operator to maintain full control while intricately moving his load. The CartCaddy WagonWheel power tugger’s ability to go 3 mph allows the machine to keep up with the operator without frustration from waiting for a slowly operating machine when operating the unit from point A to B throughout your facility

The safety stop switch positioned at the back of the handlebar box immediately kills the power, and the machine comes to a rolling stop (about 2 ft.) to prevent any possible injury from operating the device. This feature is a must when buying any piece of cart pulling equipment.

The CartCaddy WagonWheel is designed for easy maneuvering and pivoting of your loads. After the arm is attached firmly to your carts or equipment, the unit can pivot a full 180 degrees under the arm. This feature allows for turning your loads a full 90 degrees without jack knifing your cart or manually turning the front of your cart.

Standard Features

- Heavy duty steel frame

- 1,500 lb. Differential / Transaxle

- High tech speed controller

- Neutral throttle braking

- Adjustable acceleration & braking

- 3 – 12v Batteries

- Variable speed twist grip

- 0-3 mph Forward & Reverse

- Non-marking tires

- Battery discharge indicator

- Automatic charger

Optional Features

- Upgraded power package

- Extra steel

- Pintle hitch

- Ball hitch and mounting bracket

- Safety horn

- Safety light & light pole

- Maintenance-free batteries (set of 3)

- Onboard charger

- Solid fork tire upgrade

- Safety stop switch

RELATED PRODUCTS

Ideal For Any Application

DJ Products’ electric cart pushers and pullers are manufactured to take on the heaviest of equipment and materials. Providing the necessary force for directional movements, they are successful for any application and beneficial for assembly lines. These devices are ideal for any task that requires moving heavy carts and can be used both outdoors and indoors. But one of the main benefits of using our electric cart pushers and pullers is the ergonomic design that helps prevent muscle strain or other injuries that occur with manual labor. DJ Products’ electric cart pushers and pullers are ideal solutions for any application.

Enhance Employee Productivity

Our cart movers are designed to help move heavy equipment and other loads throughout your facility. These units enhance employee productivity and increase worker safety when pushing or pulling heavy materials. Both convenient and portable, our cart movers do not have pneumatic hoses or other electrical cords that can be easily tripped over. Our battery-powered solutions increase productivity and help you cut down on extra labor hours from manually moving heavy equipment. Our products fit a wide array of applications across many different industries.

Improve Workplace Safety

Investing in your business’s material handling process is essential for improving productivity, safety, and engagement. Employees will notice that your company has put their best effort to ensure safety for them, which is essential for your business. Repetitive manual labor can result in discomfort and injury. Our electric cart pusher and puller solutions take the strain off and improve safety measures for your employees. Our battery-powered solutions help prevent high employee turnover rates while enhancing employee involvement. Implementing a cart mover to your operations also prevents damage when moving materials and other heavy equipment throughout the facility.